Over a year ago, I was contacted by a Meter & Monitoring Services company who were keen to add a hydro installation to the range of sites they were already monitoring. At the time, I couldn't see that the data they collected, or the way they collected it, would add to what I was doing before. But one year on I'm rather impressed by their system.

Their set up involved installing a second energy meter in series with my existing kWh meter; the new meter collects and stores generation data and once per 24 hrs transfers it over a mobile phone link to my 'account' held on a central server; by logging into this 'account' I can view all the data and down-load both the raw data and the graphs which the data make possible.

This is the record of generation since 1st Oct 2015 to today 31st Jan 2017 as logged by the system:

...the vertical scale shows kWh generated per day; a point of note in this record is how little generation there has been in Dec / Jan 2016/17 compared with 2015 /16; the present daily yield is just 8 kWh per day whilst last year at this time it was 18 kWh, - testament to how dry this year has been.

The advantages of this system compared with what I was, and am still, doing are that it is automated, more accurate and more secure. My old system takes data from the inverter (which is less accurate than this 'industry standard' energy meter); requires me to take it manually each month (whereas this needs no human input); and requires me to keep it on my computer (whilst this system uses 'cloud storage').

All in all, I think it's quite a useful addition to the way I monitor my Powerspout... especially since for me it's free, - though that might change. But take note - it does require mobile phone reception.

...experience gained from the operation of a microhydro plant, probably of interest mostly to other Powerspout owners. At the start, in 2014, it was new and there was much to write about but as time has passed there is less. So new posts will only be written if something interesting comes along, - look below to see if there is a new post.

6.48 mm diameter nozzle delivering 0.91 l/s to the runner which is rotating at 1084 rpm and generating 225 watts into the grid at an overall efficiency of 47%.

Tuesday, 31 January 2017

Friday, 20 January 2017

After waiting...

After waiting a month for rain, I've given up waiting any longer, - yesterday I got on with measuring values for the discharge co-efficient of my nozzles. This was the job left hanging at the end of the last diary entry and is part of my aim to refine the accuracy of knowing what flow the jets deliver.

At this time of year I had hoped that rain would have been increasing the flow and that I could have done the measurements at each increase in nozzle size with little inconvenience; there being no rain, no increase in flow and no call to increase nozzles, all I could do was measure the smaller nozzles one after the other in a single blitz of measurement.

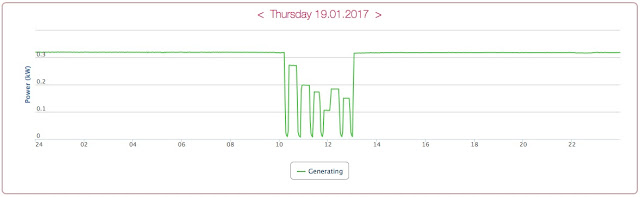

It made for a lot of exercise up and down the hill between turbine and header tank, - and for an interesting record in the on-line power trace:

The results of the experiment are presented in the following graph; on it I have also indicated the flow each nozzle delivered, as determined by measurement:

I was only able to measure the seven smallest nozzles, identified by Roman numerals I to VII; apart from one outlier in the measurement of nozzle IV (which I am at a loss to explain**), the others came in with discharge coefficients scattered around the 0.85 value; there was no obvious trend for Cd to increase or decrease with change in orifice size; I conclude from this that Cd is determined only by the design of the nozzle, - design that includes such features as its angle of taper, its length and the smoothness of the inner surface over which water is flowing. Whether Cd changes with head was something I couldn't determine with this experiment conducted as it was at one site.

Thus far so good: - from now on I will take 0.85 to be the discharge coefficient. In time there will be opportunity to take measurements for the larger nozzles VIII to XII and when available these will add weight to the picture so far obtained.

Does all this cause the earth to shift on its axis of rotation ? - no but it's still worth investigating !

**later I discovered this nozzle was badly cut explaining why it was different.

Addendum dated 2 Feb 2017

Today copious rain has made it possible to measure the Cd and flow of the remaining 5 nozzles; the results are shown in the revised chart below; overall the Cd of EcoInnovation nozzles on my site seems to be 0.85 ± 0.01.

At this time of year I had hoped that rain would have been increasing the flow and that I could have done the measurements at each increase in nozzle size with little inconvenience; there being no rain, no increase in flow and no call to increase nozzles, all I could do was measure the smaller nozzles one after the other in a single blitz of measurement.

It made for a lot of exercise up and down the hill between turbine and header tank, - and for an interesting record in the on-line power trace:

The results of the experiment are presented in the following graph; on it I have also indicated the flow each nozzle delivered, as determined by measurement:

Thus far so good: - from now on I will take 0.85 to be the discharge coefficient. In time there will be opportunity to take measurements for the larger nozzles VIII to XII and when available these will add weight to the picture so far obtained.

Does all this cause the earth to shift on its axis of rotation ? - no but it's still worth investigating !

**later I discovered this nozzle was badly cut explaining why it was different.

Addendum dated 2 Feb 2017

Today copious rain has made it possible to measure the Cd and flow of the remaining 5 nozzles; the results are shown in the revised chart below; overall the Cd of EcoInnovation nozzles on my site seems to be 0.85 ± 0.01.

Tuesday, 20 December 2016

Knowing the flow.

Putting a numerical value on the flow being delivered to your turbine isn't important to most Powerspout owners; it's sufficient to open a valve, one or two of them for a pelton, or up to four for a turgo, and let the turbine spin; the business of knowing what flow is actually being delivered in litres per second, or gallons per minute, doesn't really matter; all that matters is that the flow delivered is not greater than what is available.

In the last diary entry I suggested I know what flow each of my nozzles delivers; that the figure for each can be calculated from a formula; that the accuracy of the result given by that formula depends rather too much on the value assigned to two inputs: the nozzle discharge coefficient (Cd) and the net Head (Hn).

Today, I've been doing an experiment to check the accuracy of the figure for Cd that I've been using in the formula over the past three years, - and I've found it's way out; the true flow from each nozzle is significantly less than I've been supposing; for me, and perhaps for some other operators of Powerspouts, this has important implications as I'll go on to show, - but first the experiment:

It involved measuring flow rate by stopping the inflow to the header tank and measuring the time it took for the level to drop a measured amount; with knowledge of the dimensions of the tank, the depth dropped and the time it took, calculating the flow rate was easy. Small errors enter because the flow will change as the water level drops (but change only to a tiny extent), and because the internal dimensions of the tank are complicated by internal flanges (a 'best-guess' correction was incorporated).

To get a precise measurement of the drop in water level, two 3 mm knitting needles were mounted in a bit of wood, rigidly fixed to the tank; the tips of the needles were at different levels, a difference which could be measured to 0.02 mm with a vernier caliper; timing started when the falling water level broke the 'grab' on the tip of the higher needle, - the 'grab' being the attachment to the tip of the needle caused by surface tension, - and ended when it was broken on the lower placed needle:

Three runs were made and all provided near identical results: for the nozzle I was using it took 5 mins and 46.7 secs for the water level to drop from one needle tip to the other; calculation gave the flow rate as 1.25 litres per second whereas before I had thought it was 1.29 l/s.

Now you might think this difference to be small but its effects are big; using the figure for flow rate measured today and using it in the formula to do a 'back calculation' of Cd, instead of Cd being 0.91 as I had previously been assuming, it comes out at under 0.88.

Re-calculating the flow for each of my nozzles using a Cd of 0.88 makes each have a flow less than I had been reckoning on; what does this mean in the real world? - it means two things:

In the last diary entry I suggested I know what flow each of my nozzles delivers; that the figure for each can be calculated from a formula; that the accuracy of the result given by that formula depends rather too much on the value assigned to two inputs: the nozzle discharge coefficient (Cd) and the net Head (Hn).

Today, I've been doing an experiment to check the accuracy of the figure for Cd that I've been using in the formula over the past three years, - and I've found it's way out; the true flow from each nozzle is significantly less than I've been supposing; for me, and perhaps for some other operators of Powerspouts, this has important implications as I'll go on to show, - but first the experiment:

It involved measuring flow rate by stopping the inflow to the header tank and measuring the time it took for the level to drop a measured amount; with knowledge of the dimensions of the tank, the depth dropped and the time it took, calculating the flow rate was easy. Small errors enter because the flow will change as the water level drops (but change only to a tiny extent), and because the internal dimensions of the tank are complicated by internal flanges (a 'best-guess' correction was incorporated).

To get a precise measurement of the drop in water level, two 3 mm knitting needles were mounted in a bit of wood, rigidly fixed to the tank; the tips of the needles were at different levels, a difference which could be measured to 0.02 mm with a vernier caliper; timing started when the falling water level broke the 'grab' on the tip of the higher needle, - the 'grab' being the attachment to the tip of the needle caused by surface tension, - and ended when it was broken on the lower placed needle:

Three runs were made and all provided near identical results: for the nozzle I was using it took 5 mins and 46.7 secs for the water level to drop from one needle tip to the other; calculation gave the flow rate as 1.25 litres per second whereas before I had thought it was 1.29 l/s.

Now you might think this difference to be small but its effects are big; using the figure for flow rate measured today and using it in the formula to do a 'back calculation' of Cd, instead of Cd being 0.91 as I had previously been assuming, it comes out at under 0.88.

Re-calculating the flow for each of my nozzles using a Cd of 0.88 makes each have a flow less than I had been reckoning on; what does this mean in the real world? - it means two things:

- when I thought I was delivering the maximum flow my abstraction licence allows (3 l/s), in fact I was delivering less than this; for the future, delivering a true 3 l/s will mean more power when operating at the top limit of flow.

- 'whole system efficiency' improves with this new information and this makes to be less the factor used in the annual calculation of the total volume of water abstracted, the so-called Hydro Abstraction Factor (HAF), - used to calculate, from the kWh's produced, the volume of water abstracted; my HAF drops from 13 m³ / kWh to 12 m³ and the effect of this is to reduce the likelihood of my going over the volume I'm allowed to abstract in a 12 month period.

As carried out today, the test to verify Cd was performed using just one nozzle. The question remains as to whether the value of Cd changes with nozzles having different orifice sizes; so I'll repeat the experiment as opportunity arises to use nozzles with bigger, or smaller, orifices.

Just at the moment though, it's so dry here that an opportunity to use bigger might be a while in coming.

Subscribe to:

Posts (Atom)