The end of September marks the end of what I call my "water year", by which I mean the twelve months which is centred on those months of the year when generation is maximal.

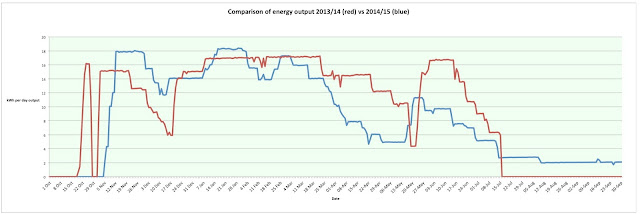

Taking this span of time makes a graph of energy output look more tidy because each year begins and ends with the time of lowest output. Here is what this year's and last year's outputs look like superimposed on each other, blue for this year, red for last:

The totals generated in each of the two years were 3,350 kWh last year and 3,216 kWh this; not very different from each other. The pattern of peaks and troughs in generation are also not very different in the two years.

By the start of October I expect there to be too little flow to be generating so, because the turbine is shut down anyway, I generally set aside this time to do the yearly de-silting of the header tank. This year however, as the blue line above indicates, a meagre daily output is still being produced, so today I have had to interrupt generation to get the job done:

The volume of water which has passed through the tank in the previous 12 months will have been in excess of 50 thousand cubic metres. With such a large volume, it is scarcely surprising that sludge collects but the amount I have scooped out today, when dry, would probably not amount to more than a tiny fraction of a cubic metre. So in fact the silt burden in the water is actually pretty low and a lack of abrasive wear on the pelton cups and nozzles reflects this.

My other bit of diary news is that I have just started on an experiment which has been stimulated by my last blog post entitled "Capping voltage". There, I alluded to the problems of circuit board failures caused by dampness. It has occurred to me that ventilating the electrical compartment with large volumes of moist air when there is a bulkhead kept cold by the temperature of the water on the other side, is a surefire recipe for creating wetness rather than reducing it.

So the plan is to seal the electrical compartment completely, pack all the spare space with

bags of silica gel, and see whether the humidity can be got down to a level where the dew point will never be reached however cold the surface of the bulkhead. That's the plan but first there's a need to measure what the humidity and temperature are before the silica gel goes in. There's also the need to keep track of what the ambient temperature rises to in the compartment, especially as the level of power output increases over the coming months. So I've made a little port hole through which to view a digital hygrometer / thermometer (£2.29 from ebay):

I'll report more fully later whether this 'sealed' approach reduces the wetness in the electrical side.

...experience gained from the operation of a microhydro plant, probably of interest mostly to other Powerspout owners. At the start, in 2014, it was new and there was much to write about but as time has passed there is less. So new posts will only be written if something interesting comes along, - look below to see if there is a new post.

6.48 mm diameter nozzle delivering 0.91 l/s to the runner which is rotating at 1084 rpm and generating 225 watts into the grid at an overall efficiency of 47%.

No comments:

Post a Comment